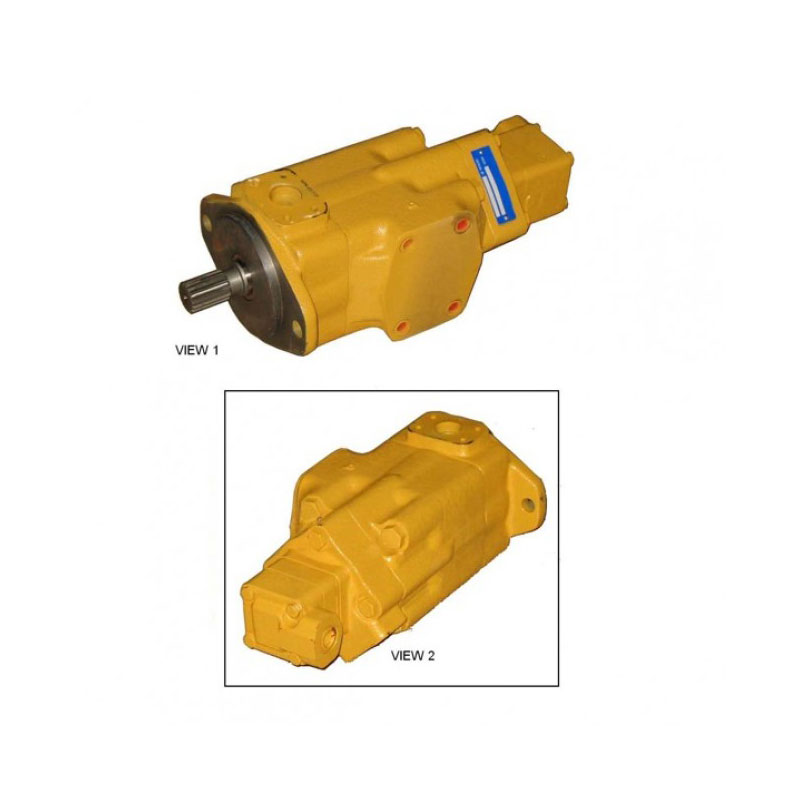

Views:

Compatible Brand:CATERPILLER

Email me WhatsApp meThe Caterpillar Vane Pump, identified by part number 1212501 (PUMP GROUP-VANE), is a critical component engineered to deliver reliable and efficient hydraulic power within heavy machinery. Designed for demanding operational environments, this basic vane pump ensures smooth and consistent fluid flow, essential for the optimal performance of your Caterpillar equipment. Its robust construction and adherence to Caterpillar's stringent quality standards guarantee long-lasting durability and superior functionality.

Part Number: 1212501 (PUMP GROUP-VANE)

Type: Basic Vane Pump for Hydraulic Systems

Approximate Item Weight: 84.6 pounds (38.4 kg)

Approximate Package Dimensions: 48 x 40 x 20 inches (122 x 102 x 51 cm)

Compatible Engines: 3116, 3126

High Efficiency: Engineered for optimal hydraulic efficiency, ensuring maximum power transfer with minimal energy loss.

Exceptional Durability: Constructed from high-quality materials, designed to withstand rigorous operating conditions and extend service life.

Reliable Performance: Provides consistent and stable hydraulic pressure, critical for the precise control and operation of heavy equipment.

Precise Control: Contributes to the smooth and responsive operation of hydraulic systems, enhancing overall machine productivity.

OEM Quality Standards: Manufactured to meet or exceed Caterpillar's original equipment specifications, ensuring perfect fit and function.

The Caterpillar Vane Pump 1212501 is specifically designed for integration into the hydraulic systems of the following Caterpillar heavy equipment:

Caterpillar Wheel-Type Loaders:

950F

950F II

The Caterpillar 950F and 950F II Wheel Loaders, powered by the 1212501 vane pump, are versatile machines widely used in various demanding industries. The hydraulic system, driven by this pump, is crucial for controlling the loader's bucket, lift arms, and steering, enabling efficient material handling and excavation.

Construction Sites: Used for loading aggregates, sand, gravel, and other building materials onto trucks, preparing sites, and backfilling trenches.

Mining Operations: Essential for moving excavated ore, overburden, and other materials in surface mines and quarries.

Waste Management: Employed in waste transfer stations and landfills for sorting, loading, and compacting waste materials.

Quarries & Aggregate Production: Vital for handling crushed rock, gravel, and sand, facilitating efficient processing and transportation.

Consider a large-scale infrastructure project where a Caterpillar 950F Wheel Loader is continuously moving tons of excavated soil and crushed concrete. The reliability of the 1212501 vane pump is paramount in such an operation. A high-performing pump ensures immediate response from the hydraulic cylinders, allowing the operator to quickly scoop, lift, and dump materials. Any lag or inconsistency in hydraulic pressure due to a faulty pump would directly impact productivity, leading to project delays and increased operational costs. The 1212501 pump's consistent pressure output and durability minimize downtime, ensuring that the loader can operate at peak efficiency for extended periods, directly contributing to the project's timely completion and cost-effectiveness.

While the 1212501 is a specific vane pump, Caterpillar offers a range of hydraulic pumps designed for various applications and equipment. Here are some related products:

Caterpillar Vane Pump 1214313:

Similar to the 1212501, this vane pump is also a key component in hydraulic systems.

Applicable Equipment: Primarily fits Caterpillar 966F and 966F II Wheel Loaders.

Caterpillar Fuel Transfer Pumps (e.g., CAT313-7770/3137770):

While not a hydraulic vane pump, fuel transfer pumps are another vital pump category for Caterpillar engines, ensuring proper fuel delivery.

Applicable Equipment: Often used in larger Caterpillar engines such as the 3512E and 3508E, found in various heavy-duty applications.

Proper installation is crucial for the longevity and optimal performance of any hydraulic pump. While specific issues for the 1212501 were not found, common problems during hydraulic pump installation and their general solutions include:

Contamination:

Problem: Introduction of dirt, debris, or old fluid residue into the new pump or hydraulic system. This is the most common cause of premature pump failure.

Solution: Thoroughly clean the entire hydraulic system (reservoir, lines, filters) before installation. Use clean, recommended hydraulic fluid and replace all filters. Store the new pump in a clean, dry environment until ready for installation.

Improper Alignment:

Problem: Misalignment between the pump shaft and the drive shaft (e.g., engine crankshaft or PTO shaft). This can lead to excessive vibration, bearing wear, and shaft seal damage.

Solution: Ensure precise alignment according to manufacturer specifications using appropriate alignment tools. Check for concentricity and angular misalignment before tightening mounting bolts.

Air Entrainment/Cavitation:

Problem: Air trapped in the hydraulic system or suction line, leading to noise, erratic operation, reduced efficiency, and internal damage (cavitation).

Solution: Properly bleed the system of air after installation. Ensure all suction line connections are airtight and submerged in fluid. Check for any kinks or restrictions in the suction line that could cause vacuum and air ingress.

Incorrect Fluid Level or Type:

Problem: Using the wrong type of hydraulic fluid or having an insufficient fluid level in the reservoir.

Solution: Always refer to the Caterpillar service manual for the correct hydraulic fluid type and viscosity. Ensure the fluid level is within the specified range at all times, especially during operation.

Loose Connections:

Problem: Loose hydraulic hose fittings or mounting bolts can lead to leaks, pressure loss, and vibration.

Solution: Torque all bolts and fittings to the manufacturer's recommended specifications. Double-check all connections after initial run-up.

| Column 1 | Column 2 | Column 3 | Column 4 | Column 5 | Column 6 | Column 7 | Column 8 | Column 9 |

|---|---|---|---|---|---|---|---|---|

| 1002961 | 3G2195 | 3G2806 | 4J1781 | 4K4634 | 6J1578 | 7J0576 | 1U2220 | 6E6666 |

| 1002961 | 3G2196 | 3G2807 | 4J1782 | 4K4835 | 6J1579 | 7J0577 | 1U2221 | 7J0583 |

| 1013451 | 3G2197 | 3G2832 | 4J2401 | 4T0416 | 6J2186 | 7J0578 | 1U3969 | 9J5048 |

| 1080502 | 3G2198 | 3G2833 | 4J2460 | 4T0417 | 6J3138 | 7J0580 | 3G4601 | 9J5049 |

| 1243503 | 3G2199 | 3G2834 | 4J2461 | 4T0422 | 6J6614 | 7J0581 | 3G6846 | 9J5050 |

| 1243504 | 3G2200 | 3G2835 | 4J3447 | 4T1893 | 6J7391 | 7J0880 | 3G7412 | 9J5053 |

| 1364815 | 3G2201 | 3G2836 | 4J3538 | 4T2008 | 6J7625 | 7J1397 | 3G7637 | 9J5056 |

| 1555091 | 3G2233 | 3G2837 | 4J4707 | 4T2626 | 6J7630 | 7J1780 | 3G7638 | 9J5061 |

| 1U3506 | 3G2234 | 3G2875 | 4J5128 | 4T3196 | 6J7635 | 7J1921 | 3G7639 | 9J5070 |

| 1U3507 | 3G2235 | 3G2889 | 4J6790 | 4T6869 | 6J7938 | 7J3978 | 3G7640 | 9J5080 |

| 1U3508 | 3G2236 | 3G7651 | 4J6843 | 5J0100 | 7J0552 | 7J3979 | 4D4661 | 9J5082 |

| 1U3513 | 3G2237 | 3G7652 | 4J7474 | 5J0101 | 7J0553 | 7J5567 | 4T0509 | 9J5083 |

| 1U0532 | 3G2238 | 3G7653 | 4J7948 | 5J0925 | 7J0554 | 7J7416 | 4T6847 | 9T0486 |

| 1U2652 | 3G2239 | 3G7654 | 4J7949 | 5J1251 | 7J0555 | 7J7962 | 4T6914 | 9T3866 |

| 1U2664 | 3G2243 | 3G7655 | 4J8448 | 5J3646 | 7J0556 | 7J7963 | 5U0557 | 9T6123 |

| 1U2665 | 3G2717 | 3G7656 | 4J8478 | 5J4502 | 7J0557 | 7J7964 | 6E2063 | 9T7916 |

| 1U2666 | 3G2718 | 3G7657 | 4J8479 | 5J4894 | 7J0558 | 7J7966 | 6E2064 | 1003414 |

| 1U2667 | 3G2719 | 3G7658 | 4J8480 | 5J5070 | 7J0559 | 7J7967 | 6E2928 | 1043128 |

| 1U2668 | 3G2720 | 3G7659 | 4J8483 | 5J5924 | 7J0560 | 7J7968 | 6E2929 | 1052155 |

| 1U2669 | 3G2721 | 3G7660 | 4J8484 | 5J6217 | 7J0561 | 8J2060 | 6E2930 | 1050636 |

| 1U2670 | 3G2722 | 3G7661 | 4J8485 | 5J7517 | 7J0562 | 8J6293 | 6E2931 | 1206744 |

| 1U2671 | 3G2723 | 3G7662 | 4J8489 | 5J8764 | 7J0563 | 8J8716 | 6E4718 | 1212501 |

| 1U3505 | 3G2746 | 3G7663 | 4J8490 | 5J9852 | 7J0564 | 9J0473 | 6E4730 | 1314099 |

| 1U3519 | 3G2747 | 3G7664 | 4J8491 | 650710 | 7J0565 | 9J0739 | 6E5539 | 1214019 |

| 1U3952 | 3G2748 | 3G7665 | 4J8492 | 6E2387 | 7J0566 | 9J4863 | 6E5831 | 1214313 |

| 1U3953 | 3G2749 | 3G7666 | 4J8493 | 6E2396 | 7J0568 | 9J7890 | 6E6266 | 1214512 |

| 3G1266 | 3G2750 | 3G7667 | 4J8494 | 6E4258 | 7J0569 | 9J7891 | 6E6418 | 1236765 |

| 3G1267 | 3G2751 | 3K7943 | 4J8495 | 6E4269 | 7J0570 | 9J7892 | 6E6476 | 1238509 |

| 3G1268 | 3G2752 | 3K8301 | 4J8496 | 6E4719 | 7J0571 | 9J9852 | 6E6482 | 1287228 |

| 3G1269 | 3G2801 | 3K8926 | 4J8497 | 6J0050 | 7J0572 | 9N9910 | 6E6483 | 1570956 |

| 3G1270 | 3G2802 | 4J0990 | 4J8933 | 6J1101 | 7J0573 | 9T1697 | 6E6559 | 1629207 |

| 3G1271 | 3G2803 | 4J1310 | 1417916 | 1465074 | 7J0574 | 9T2200 | 1465076 | 1914610 |

| 3G2194 | 3G2804 | 4J1401 | 4K1944 | 6J1543 | 7J0575 | 9T5336 |